The protective rubber coating protects fragile magnet from chipping and corrosion. In the meanwhile, rubber coating can serve an excellent slide resistance or shear force by enhancing friction without scratching working face. Therefore, rubber coated magnet is generally regarded as an ideal sustained solution for both indoor and outdoor magnetically holding, mounting, and fixing applications.

包胶磁铁也被称为包胶吸盘或包胶吸力件,是由烧结钕铁硼磁体、导磁不锈钢板和橡胶外壳共同组成。橡胶外壳可最大程度避免磁体出现破损和腐蚀。

包胶磁铁内部磁路

当大部分磁通是沿导磁介质而不是空气闭合时,磁性系统方可具有最佳的磁强度。对于包胶磁铁,其磁性系统中相邻两个磁体需具有不同极性。以A43型号为例,磁体极性交替排布和同极排布的吸力模拟值分别可以达到123.0N和78.7N,即成本相同的情况下具有更高的吸力值。

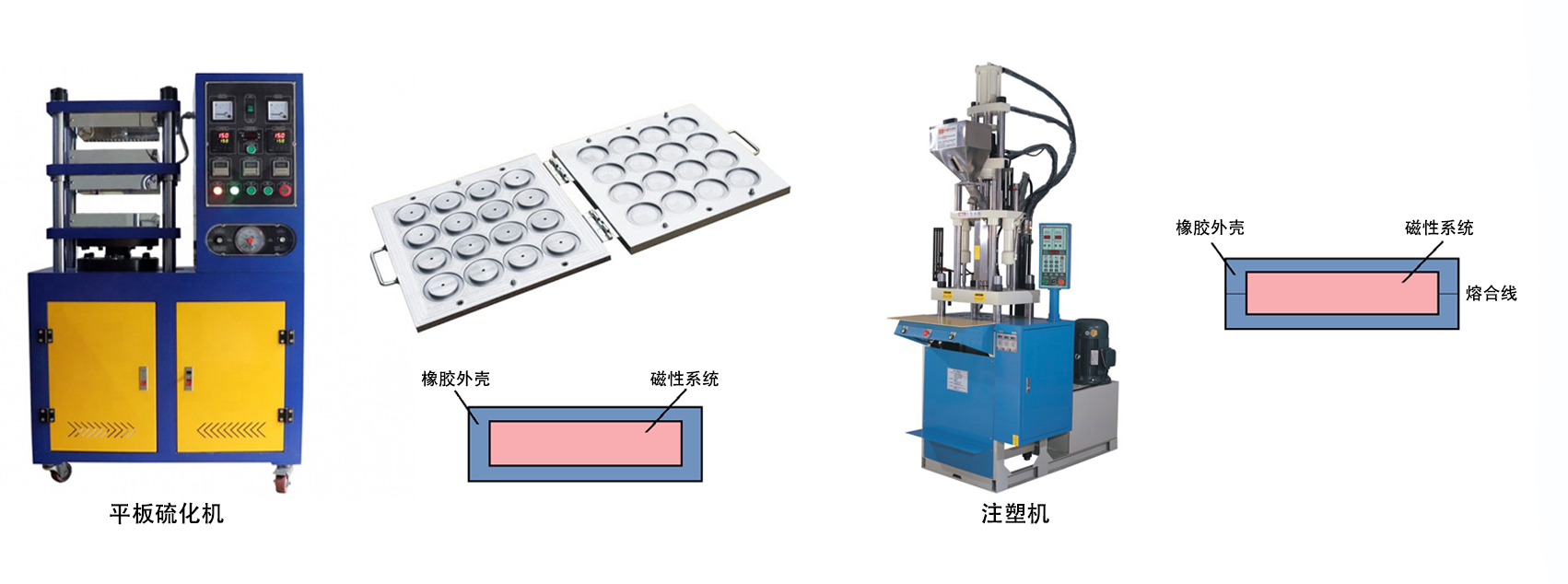

包胶磁铁包胶工艺

包胶磁铁的包胶

Encapsulation process of rubber coated magnet is processed via vulcanization or injection molding technology. Vulcanization and injection molding technology is corresponding to vulcanized silicon rubber and thermo-plastic-rubber material (TPR), respectively. Injection molding technology of rubber coated magnet is belonging to overmolding process which involves 2 separate molds. The first mold produces a rubber part with cavity for the magnetic system. Magnetic system is then placed into the first rubber part. The assembly is subsequently inserted into the second mold where the second half of rubber part in injected, covering the magnetic system and fusing with the first half of the rubber part. For rubber coated magnet, injection molding technology is the more conventional encapsulation process compared with vulcanization technology due to the production efficiency, raw material cost, utilization rate of recycled material, and color flexibility. Even vulcanization technology is generally condemned for relatively higher cost, but vulcanized silicon rubber coating can serve more superior durability and slide resistance to rubber coated magnet.

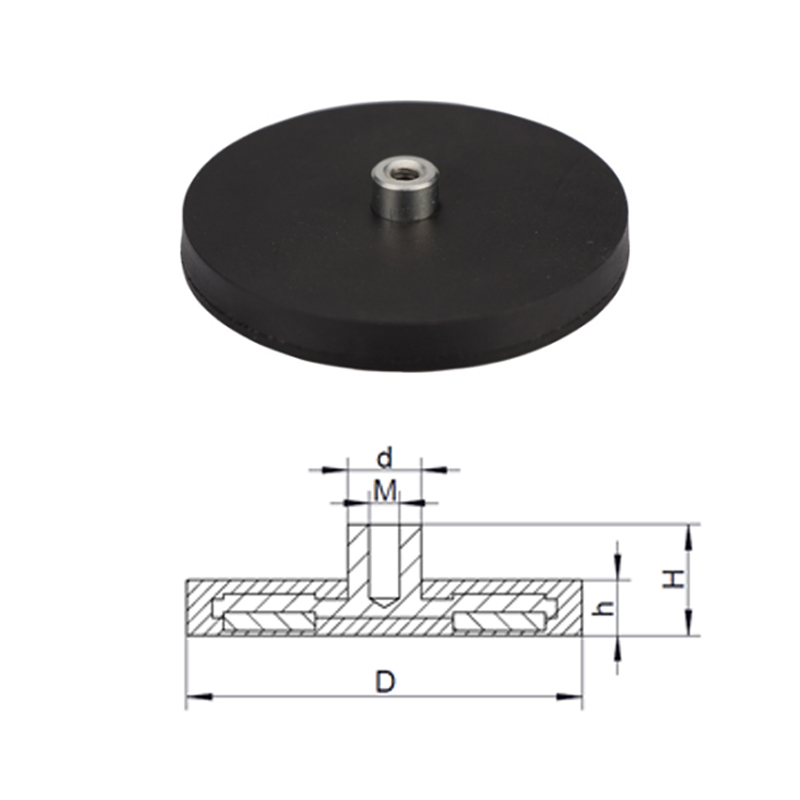

A系列

| 型号 | D (mm) | 螺纹尺寸 | d (mm) | h (mm) | H (mm) | 单重 (g) | 吸力 (kg) |

| 22 | 22 | M4/M5/M6 | 8 | 6 | 11.5 | 11 | 3.5 |

| 31 | 31 | M4/M5/M6 | 8 | 6 | 11.5 | 19 | 7.5 |

| 36 | 36 | M4/M5/M6 | 8 | 7 | 11.5 | 24 | 8 |

| 43 | 43 | M4/M5/M6 | 8 | 6 | 10.5 | 31 | 10 |

| 66 | 66 | M5/M6/M8 | 12 | 8 | 13.5 | 100 | 20 |

| 88 | 88 | M6/M8/M10 | 12 | 8 | 13.5 | 179 | 42 |

| 颜色及吸力可接受定制。 | |||||||

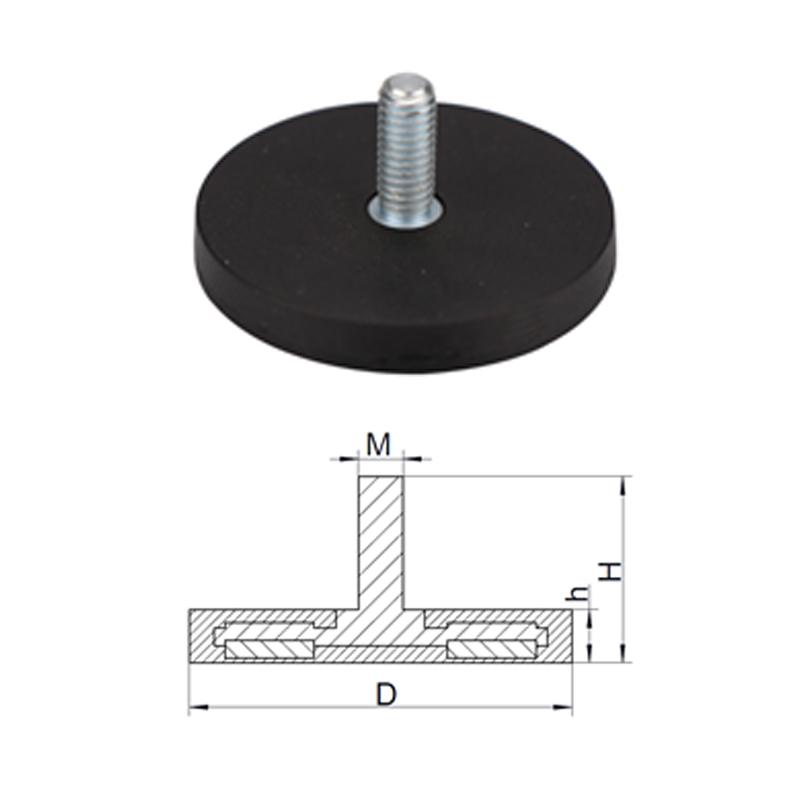

B系列

| 型号 | D (mm) | 螺纹尺寸 | h (mm) | H (mm) | 单重 (g) | 吸力 (kg) |

| 22 | 22 | M4/M5/M6 | 6 | 13 | 11 | 3.5 |

| 31 | 31 | M4/M5/M6 | 6 | 21 | 22 | 7.5 |

| 36 | 36 | M4/M5/M6 | 7 | 22 | 27 | 8 |

| 43 | 43 | M4/M5/M6 | 6 | 21 | 34 | 10 |

| 66 | 66 | M5/M6/M8 | 8 | 23 | 100 | 20 |

| 88 | 88 | M6/M8/M10 | 8 | 23 | 184 | 42 |

| 颜色及吸力可接受定制。 | ||||||

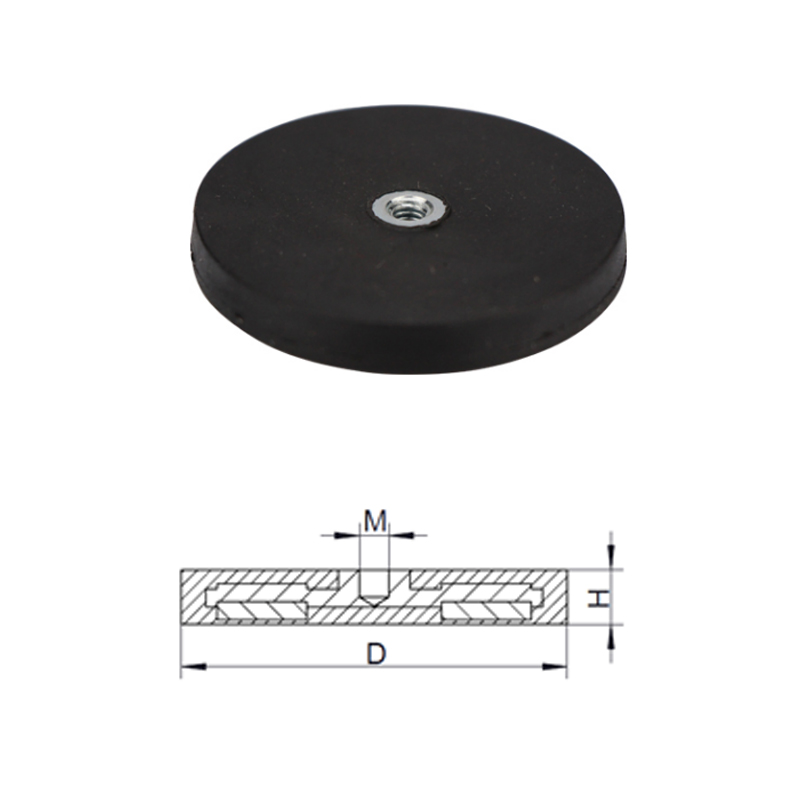

C系列

| 型号 | D (mm) | 螺纹尺寸 | H (mm) | 单重 (g) | 吸力 (kg) |

| 22 | 22 | M4/M5/M6 | 11.5 | 11 | 3.5 |

| 31 | 31 | M4/M5/M6 | 11.5 | 19 | 7.5 |

| 36 | 36 | M4/M5/M6 | 11.5 | 24 | 8 |

| 43 | 43 | M4/M5/M6 | 10.5 | 31 | 10 |

| 66 | 66 | M5/M6/M8 | 13.5 | 100 | 20 |

| 88 | 88 | M6/M8/M10 | 13.5 | 179 | 42 |

| 颜色及吸力可接受定制。 | |||||