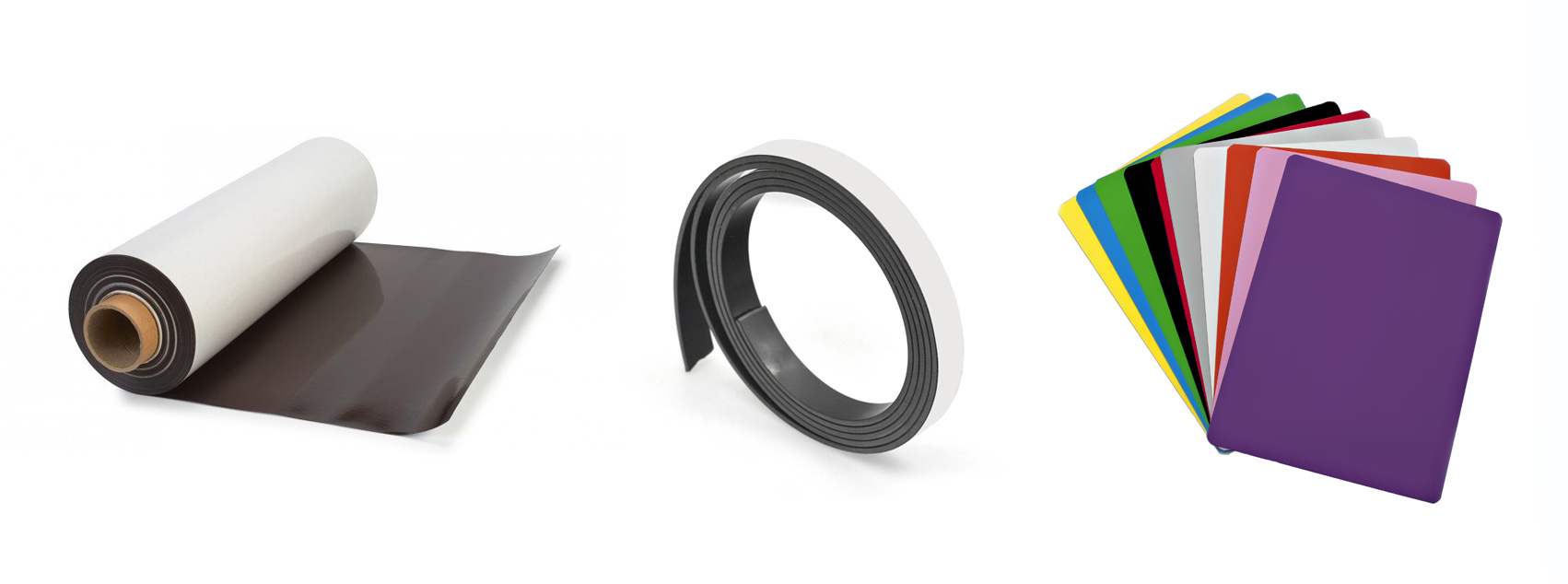

Flexible magnets are a type of magnet made by blending ferrite magnetic powder with rubber which is then calendered to produce strip, sheet, or roll. Bonded magnets can be divided into compression molded magnets, injection molded magnets, extruded magnets, and calendered magnets base on processing technology. Flexible magnets are belonging to the calendered magnets. Flexible magnets can be easily produced into all kinds of shapes and sizes from a few millimeters to tens of meters owing to exceptional elasticity, flexibility, and machinability. Conventional post processing includes blanking, cut-off, punching, and bending.

Flexible magnets are generally laminated by colorful PVC, adhesive tape, or polychrome printing. Fridge magnets are undoubtedly the most representative application of flexible magnets. Fridge magnets are often utilized to post items or served as decoration. Fridge magnets can be provided in a wide variety of shapes and sizes; therefore, many people treat them as a popular souvenir and collectible objects. Due to the limitations of low magnetic performance, axially multipole magnetization applies to enhance the pull force of the fridge magnet.

Flexible magnets are widely served for either civilian uses or industrial applications. Ring magnets wound by axially multipole magnetized magnetic strips are much easier to realize ultra-multipole magnetization compared with whole ring magnets, then enable it to serve for fan motors and the vast majority of linear or rotary magnetic encoder. In addition to the frequently-used ferrite based magnets, Fe3B based magnets with have high Br and low Hcj is also available.